Industrial hydraulic valve application innovation leads the new trend of the industry

create_time:2024-08-15 author:

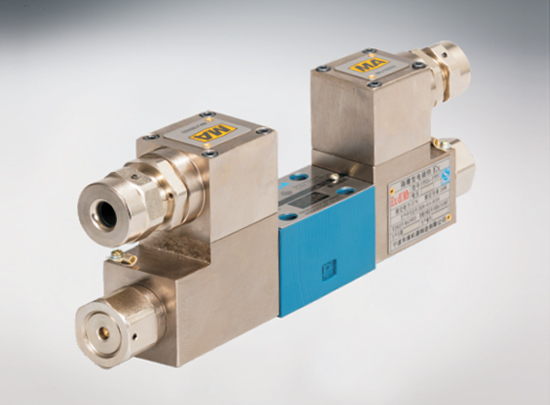

In today's rapidly developing industrial field, hydraulic technology, as a key means of transmitting power to various mechanical equipment, is gaining increasing attention. In particular, industrial hydraulic valves, as core components for controlling and regulating liquid flow, have shown great potential and innovation in many fields. From traditional machinery manufacturing to advanced automation control systems, the application of industrial hydraulic valves not only improves the performance and efficiency of equipment, but also promotes technological progress and innovation in the industry.

In the field of heavy machinery control, industrial hydraulic valves play an indispensable role. For example, in engineering machinery such as excavators, cranes and loaders, hydraulic valves ensure the fineness and smoothness of mechanical operation by precisely controlling the flow and pressure of oil, greatly improving the safety and efficiency of construction operations. This application not only requires hydraulic valves to have high reliability and durability, but also puts higher requirements on their control accuracy.

With the continuous advancement of automation technology, the application of industrial hydraulic valves in automated production lines is becoming more and more extensive. In automated machine tools, assembly lines and material handling systems, hydraulic valves achieve high efficiency and high stability in the production process by precisely controlling the action of actuators. Especially in high-precision machining and assembly of complex components, the rapid response and precise control capabilities of hydraulic valves ensure the processing quality and production efficiency of products.

Emerging clean energy fields, such as wind power and hydropower, have also begun to widely use industrial hydraulic valves. In these fields, hydraulic valves are used to control the angle of blades or the direction of water flow, thereby optimizing the capture and conversion efficiency of energy. This not only improves the efficiency of energy utilization, but also meets the requirements of sustainable development and environmental protection worldwide.

The innovative application of industrial hydraulic valves is also reflected in the context of intelligent manufacturing and Industry 4.0. By integrating sensors and Internet of Things technology, hydraulic valves can achieve condition monitoring, fault diagnosis and remote control, greatly improving the intelligence level and maintenance efficiency of the system. The application of these technologies makes industrial hydraulic valves not only a simple control component, but also an important node in the smart factory network.

The diversified application of industrial hydraulic valves not only shows the wide application and important role of hydraulic technology in modern industry, but also reflects the spirit of continuous innovation and pursuit of excellence of enterprises. In the future, with the further development of technology and the continuous increase in industry demand, the application of industrial hydraulic valves will be more diversified and intelligent, injecting more vitality into promoting industrial development.

The innovative application of industrial hydraulic valves not only demonstrates technological progress, but also brings new opportunities and challenges to the industry. Enterprises need to continue to explore and practice to grasp the pulse of industry development and lead the future of hydraulic technology.

English

English

Español

Español

русский

русский

français

français

Deutsch

Deutsch