Global Hydraulic Valve Market Development Trends: Innovation and Diversification Lead New Industry Trends

create_time:2024-09-02 author:

As one of the core components of modern industrial systems, the diversification of hydraulic valve types and technologies is driving innovation and development in the global market. With the advancement of industrial automation and the increasing demand for more efficient systems, the hydraulic valve industry is undergoing a transformation, and the emergence of various new valves meets the needs of different fields.

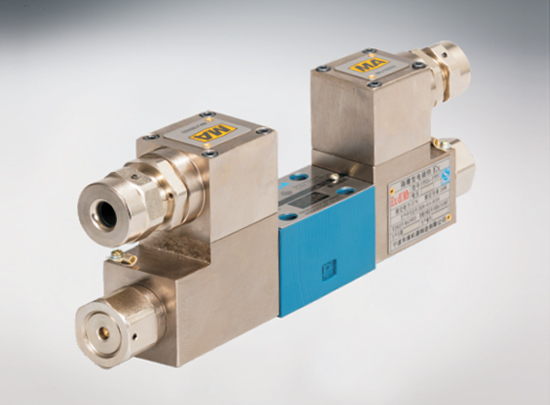

1. Electronically controlled hydraulic valves: the future of intelligence

In recent years, electronically controlled hydraulic valves have attracted attention for their precise control capabilities and efficient energy utilization. These valves are operated by electronic control systems, which can achieve higher response speeds and more detailed flow regulation, and are widely used in autonomous vehicles and high-precision manufacturing equipment. Compared with traditional hydraulic valves, electronically controlled valves can better adapt to complex operating environments and provide more stable performance.

2. Adjustable flow valves: improving system flexibility

Adjustable flow valves are favored because they can adjust the flow according to actual needs. This valve is usually equipped with a flow control device, which can provide optimal flow distribution under different working conditions, greatly improving the flexibility and efficiency of the system. Especially in application scenarios where dynamic adjustment of hydraulic system performance is required, such as construction machinery and agricultural equipment, adjustable flow valves show great advantages.

3. Hydraulic control check valve: ensuring system safety

Hydraulic control check valve is an important safety component, mainly used to prevent reverse flow in hydraulic systems, thereby protecting the system from potential damage. This valve is often used in application scenarios that require high reliability, such as aerospace and military equipment. Hydraulically controlled check valves can effectively prevent liquid backflow in hydraulic systems and ensure the safe operation of equipment.

4. Pressure reducing valve: optimizing pressure management

The pressure reducing valve plays a vital role in the hydraulic system. Its main function is to maintain the pressure stability in the system and prevent excessive or low pressure from damaging the system. Modern pressure reducing valves use advanced materials and designs to maintain excellent performance under high pressure and high flow conditions. Such valves are widely used in various industrial applications, especially in those fields with strict requirements for pressure control.

5. Multi-way valve: integrated solution

Multi-way valves can integrate multiple hydraulic functions into one valve body, thereby reducing pipe connections and simplifying system design. This valve is particularly suitable for applications with limited space or requiring high integration, such as mining machinery and engineering equipment. The design optimization of the multi-way valve makes the hydraulic system more compact, improves the reliability of the system and the convenience of maintenance.

Industry Outlook

With the continuous advancement of technology and the diversification of industrial needs, the types and functions of hydraulic valves will continue to expand. The future hydraulic valve market will pay more attention to the trend of intelligence, energy saving and environmental protection, and multi-functional integration. Manufacturers and suppliers are committed to improving the performance and application range of hydraulic valves through innovative design and material technology to meet the changing market needs.

In summary, the diversification and innovation of hydraulic valves are leading the development trend of the industry. From intelligent control to flow regulation, from safety assurance to pressure management, hydraulic valves play an increasingly important role in industrial systems. With the continuous advancement of technology, future hydraulic valves will be more intelligent and efficient, providing more powerful and flexible support for various industrial applications.

English

English

Español

Español

русский

русский

français

français

Deutsch

Deutsch