Understanding the Sophistication of Pilot Operated Relief Valves: A Game-Changer in Fluid Control Systems

create_time:2024-08-02 author:

Understanding the Sophistication of Pilot Operated Relief Valves: A Game-Changer in Fluid Control Systems

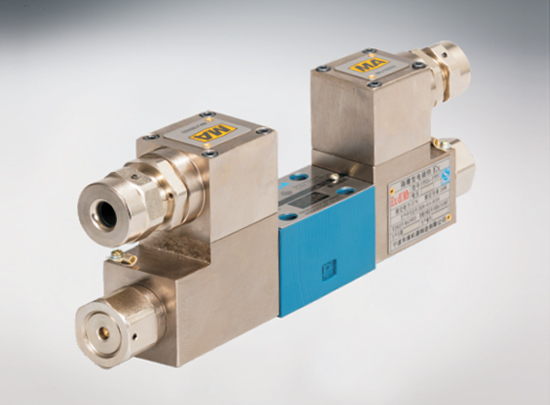

In the intricate world of fluid control and safety mechanisms, the pilot operated relief valve (PORV) stands out as a critical component, ensuring system integrity and operational safety. Designed to protect against overpressure conditions in a wide range of industrial applications, these valves have become indispensable in managing pressures effectively and efficiently.

The Essence of Pilot Operated Relief Valves

A pilot operated relief valve is a specialized type of valve engineered to maintain system pressures within safe operating limits. Unlike conventional direct acting relief valves, which respond immediately to pressure changes, PORVs utilize a separate pilot mechanism to control the valve's operation. This pilot mechanism can be a smaller valve or a sensing device that monitors pressure levels and triggers the main valve to open when the predetermined set pressure is exceeded.

How Pilot Operated Relief Valves Work

When system pressure reaches the set point, the pilot valve opens, allowing a small amount of fluid to flow, which then acts upon a diaphragm or piston within the main valve assembly. This action causes the main valve to open gradually, releasing excess pressure to the environment or a designated discharge area. Once the system pressure returns to normal, the pilot valve closes, and the main valve follows suit, sealing off the flow once again.

Advantages of Pilot Operated Relief Valves

1. Enhanced Precision: PORVs provide a higher level of accuracy in pressure control compared to standard relief valves. This is particularly beneficial in applications where pressure variations must be tightly controlled to ensure optimal performance and safety.

2. Increased Reliability: By utilizing a pilot mechanism, these valves are less prone to wear and tear, resulting in extended service life and reduced maintenance costs.

3. Superior Capacity: PORVs can handle significantly higher flow rates than direct acting valves, making them ideal for high-pressure and high-capacity systems.

4. Versatility: These valves can be found in various industries, including oil and gas, chemical processing, power generation, and petrochemicals, where they play a crucial role in safeguarding personnel and equipment.

Innovations in Pilot Operated Relief Valve Technology

Advancements in valve technology have led to the development of electronically controlled pilot operated relief valves. These valves integrate electronic sensors and actuators to monitor and control pressure more accurately. They can also communicate with central control systems, providing real-time data for monitoring and maintenance purposes.

The Future of Pilot Operated Relief Valves

As industries strive for higher efficiency and safety standards, the demand for advanced PORVs is expected to grow. Manufacturers are investing in research and development to create more durable, intelligent, and adaptable valves that can withstand harsher conditions and perform with greater precision.

Pilot operated relief valves are a testament to engineering ingenuity in fluid control systems. Their ability to maintain pressures within safe parameters is vital for the smooth operation of industrial processes. As technology evolves, PORVs will continue to play a pivotal role in ensuring safety and reliability in diverse applications around the world.

English

English

Español

Español

русский

русский

français

français

Deutsch

Deutsch