What is a Proportional Directional Valve?

create_time:2024-10-16 author:

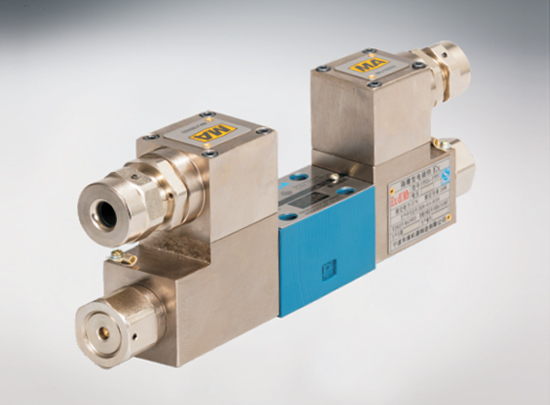

A Proportional Directional Valve is a control element commonly used in hydraulic and pneumatic systems that can precisely regulate the flow direction and flow rate of a fluid. Unlike traditional directional valves, proportional directional valves not only control the direction of the fluid, but also adjust the flow rate and pressure according to the input signal, providing more precise control.

Working Principle of Proportional Directional Valve

A proportional directional valve controls the position of the valve core through an electrical signal (usually a current or voltage signal). Depending on the strength of the input signal, the valve core moves within the valve body, changing the flow path of the fluid. This valve is unique in that it can provide continuously variable flow rates, unlike traditional directional valves that only provide two or more fixed flow options.

A proportional directional valve is usually electromagnetically driven, and its core is a proportional solenoid that controls the displacement of the valve core by adjusting the current. When the current increases, the valve core opens more and the flow rate increases; when the current decreases, the valve core closes and the flow rate decreases. This continuous control method enables the proportional directional valve to achieve precise flow regulation, suitable for applications that require delicate control.

Main Applications of Proportional Directional Valve

Proportional directional valves are widely used in hydraulic and pneumatic systems that require precise control. For example:

Industrial Automation: In automated production lines, proportional directional valves can be used to control the speed and force of the robot arm, thereby improving production efficiency and precision.

Hydraulic Systems: In hydraulic equipment, proportional directional valves are often used to regulate oil flow to ensure precise control of system pressure and flow, and optimize equipment performance and energy efficiency.

Mobile Equipment: For example, in heavy machinery such as cranes and excavators, proportional directional valves can regulate the movement of working tools for precise operational control.

Advantages of Proportional Directional Valve

Precise Control: Proportional directional valves can provide precise flow and pressure control according to different needs, especially for dynamically changing loads and working conditions.

Efficiency: By precisely adjusting the flow, proportional directional valves can maximize system efficiency, reduce energy waste, and improve the response speed of equipment.

Flexibility: They can provide different working modes according to system requirements, such as gradually adjusting the flow or maintaining a constant flow, to meet the needs of various applications.

In general, the Proportional Directional Valve is a highly precise control element that adjusts the direction and flow of fluids through proportional control electrical signals. It is widely used in hydraulics, pneumatics, and industrial automation. It provides higher control accuracy, efficiency, and flexibility, enabling modern machinery and equipment to perform well in complex and changing working environments.

English

English

Español

Español

русский

русский

français

français

Deutsch

Deutsch