What is a Double Pilot Operated Check Valve?

create_time:2024-04-29 author:

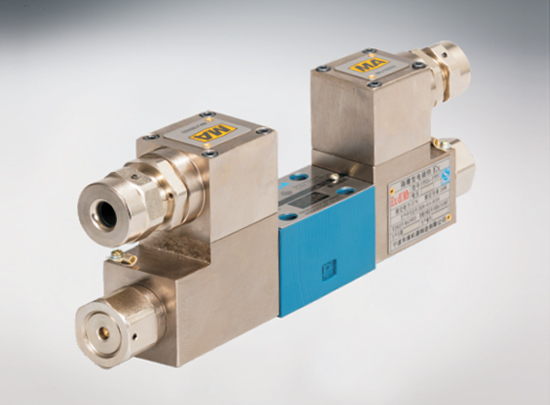

In the intricate world of hydraulic systems, where control and precision are non-negotiable, the double pilot operated check valve emerges as a pivotal component. This specialized valve is designed to lock and maintain a load in position, ensuring safety and stability in various applications. Let's delve into the mechanics and applications of the double pilot operated check valve and understand its significance in the industrial landscape.

Understanding Double Pilot Operated Check Valves

A double pilot operated check valve, often abbreviated as DPOCV, is a type of non-return valve that allows free flow of fluid in one direction and prevents flow in the opposite direction unless actuated by a pilot pressure. Unlike simple check valves, the double pilot operated check valve has two pilot lines that provide control in both directions.

The "double" aspect refers to the valve having two seats, which allow for the control of flow in both directions of a hydraulic circuit. Each seat is connected to a pilot line; when pressure is applied through the pilot line, it opens the corresponding seat, allowing fluid to flow in the reverse direction.

The Mechanics Behind the Valve

The operation of a double pilot operated check valve is all about balance and control. In its default state, the valve is closed, preventing any fluid from passing through. When fluid enters the valve under pressure, it pushes against a poppet, compressing a spring and allowing flow in the intended direction. To reverse the flow, pilot pressure must be applied to the opposite side of the valve, overcoming the spring force and enabling the fluid to return.

This mechanism is crucial in hydraulic systems that require a load to be held stationary for a period, such as a raised forklift or a hydraulic press in a paused position. The valve ensures that the load will not drop unexpectedly, which could lead to equipment damage or operator injury.

Applications of Double Pilot Operated Check Valves

The applications of double pilot operated check valves are vast and varied. They are commonly used in mobile hydraulics, such as in construction equipment like excavators and loaders, where they help maintain the position of an arm or bucket. In industrial settings, these valves are found in machines that require precise movement control, such as in material handling systems, manufacturing automation, and complex machinery.

Their use is not limited to heavy machinery; double pilot operated check valves are also integral in systems where safety is paramount. For instance, in hydraulic elevators and aerial work platforms, they prevent sudden drops, contributing to the overall safety mechanisms of these systems.

The Importance of Double Pilot Operated Check Valves

The importance of double pilot operated check valves in industrial and mobile hydraulic systems cannot be overstated. They are essential for:

- Safety: They prevent the unintended movement of loads, protecting both the machinery and the operators.

- Precision: They allow for the fine control of hydraulic actuators, which is crucial in processes that require exact positioning.

- Reliability: They ensure that hydraulic systems operate consistently, with minimal risk of failure due to load movement.

In all, Double pilot operated check valves are a testament to the sophistication and safety-conscious design in modern hydraulic systems. As industries continue to push the boundaries of technology and machinery, the demand for reliable components like the DPOCV is only set to increase. Understanding the functionality and applications of these valves is vital for anyone involved in the design, operation, or maintenance of hydraulic systems, where precision and safety are of the utmost importance. As we continue to innovate and evolve in the industrial sector, the double pilot operated check valve will remain an indispensable ally in the quest for greater control and stability.

English

English

Español

Español

русский

русский

français

français

Deutsch

Deutsch