Revealed: Three different types of hydraulic valves subvert traditional hydraulic systems

create_time:2024-03-04 author:

In various fields of modern industry, hydraulic systems play a vital role. From heavy machinery to precision manufacturing, hydraulic valves are used in a wide range of applications. Recently, industry experts have conducted an in-depth discussion on the classification of hydraulic valves and revealed three different types of hydraulic valves. Now we will introduce them in detail.

What are the 3 different types of hydraulic valves?

The three different types of hydraulic valves are directional control valves, pressure control valves, and flow control valves. These valves vary in design and function, but all play a vital role in improving system efficiency and performance.

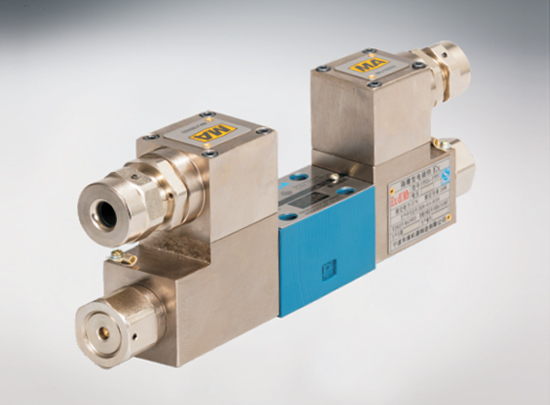

First of all, the directional control valve is a key component in controlling the direction of liquid flow. They can be simple 2/2-way valves or complex multi-way valves used to switch flow between multiple channels. Valves of this type are particularly important in hydraulic systems because they determine the flow path of the fluid, thereby affecting the direction and pattern of movement of the mechanical components.

Next, the pressure control valve is the guardian that maintains the stable operation of the system. They prevent overloading by regulating system pressure and ensuring that the hydraulic system works within a safe range. Such valves include relief valves, pressure reducing valves, etc., which sense pressure changes and adjust accordingly to protect the system from damage and ensure the smooth operation of mechanical equipment.

Finally, the flow control valve is responsible for regulating the amount of liquid flowing through the system and controlling the speed and smoothness of mechanical movement. By precisely controlling flow, these valves ensure precise and repeatable mechanical operation, which is especially important for applications requiring high precision.

These three types of hydraulic valves each perform their own duties and together form the core of the hydraulic system. As technology continues to advance, these hydraulic valves are becoming more sophisticated and able to meet the needs of more complex and demanding industrial applications. Experts believe that in-depth research and improvement of these hydraulic valves will open a new chapter in the future development of hydraulic technology and promote industrial manufacturing to develop in a more efficient and smarter direction.

English

English

Español

Español

русский

русский

français

français

Deutsch

Deutsch